Sheet plastic

Information on Sheet plastic

Sheet plastic are thin pallet-sized sheet made of plastic, heavy laminated kraft paperboard, or corrugated fiberboard used in commercial shipping. Often, these replace the use of traditional wooden pallets. The unit load is usually stretch wrapped or shrink wrapped for stability.

Description of sheet plastic

The sheet plastic is used as a unit load support device in vehicle delivery and transportation of products. When sheet plastic are supported by a pallet board, roller conveyor surface, flat load carrying surface, or a cart or lift truck, the structural strength of the sheet plastic supports the product loads weight. With the sheet plastic supported by one of these transportation devices the unit load can easily be transported both internally within a facility and externally between two facility locations.

Sheet plastic types

There are several types of sheet plastic that can be used for the transportation of a unit load depending upon the desired use of the sheet. The sheet plastic is shaped and dimensioned to the size of the product or unit load. The type of sheet plastic varies depending on both the number of lip extensions and the material from which it is manufactured.

The variation used would depend on the loading patterns, unit load parameters, and desired maneuverability of the sheet plastic/unit load. Normally, the thickness of the sheet plastic is less than 0.5 inches.

For most warehouses, plant functional material handling equipment, and the travel-path clearances, this fraction of an inch height increase does not stage a problem. When designing an in-house transportation path for the sheet plastic unit load, the sheet plastic has a four to six inch lip (tab) that extends beyond one or more of the sides of the sheet plastic. The lip extensions permit a push-pull device to lift the sheet plastic unit load.

Single lip sheet plastic

The first type of sheet plastic is the single lip (tab) sheet plastic.

With a single lip, the lip faces the narrow part of the rectangular shaped unit load and the delivery truck door. This sheet plastic variation maximizes the delivery truck’s space utilization and loading and unloading process productivity. Also, with a single lip, the travel path clearance is minimized as the lip facing the unit load carrier.

Multi-lip sheet plastic

The second type of sheet plastic is the multi-lip sheet plastic. This type of sheet plastic is generally used on a container placed onto a railroad car or an ocean delivery vehicle due to the necessary loading/unloading patterns. This allows a loading device to load the sheet plastic unit load from one side and an unloading device to unload the load from another side depending on the number and pattern of the remaining lips.

Sheet plastic Lip handling options

During the transportation of your sheet plastic, there are several options for handling the sheet plastic’s lip.

- Leave the lip extended allowing for additional clearance for the travel path.

- Tape the lip against the unit load if additional push-pull activities are required.

- Cut the lip from the sheet plastic if no additional push-pull activities are required.

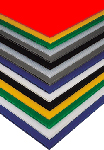

Sheet plastic materials

Corrugated sheet plastic

The corrugated fiberboard consists of two kraft liner board outer surfaces with a corrugated interior that is bonded together with adhesive or glue. This bonded material provides the necessary strength for the push-pull device to clamp the sheet plastic once or twice. There are several disadvantages associated with this type of sheet plastic material including that it is not very durable, moisture resistant, resistant to high humidity or usable in cold storage areas. The advantages associated with this material are low cost, one-way use, and its ability to be moved by a conveyor or lift truck with a sheet plastic device.

Fiberboard or solid kraftboard sheet plastic

The fiberboard (thick paperboard) sheet plastic consists of several layers of solid kraft paperboard sheets laminated together. The bonding of layers of several flat solid kraftboard sheets increases the sheet plastic’s non-tear strength. This, in return, allows the sheet plastic to be used several times and in different temperatures. In addition, some fiberboard sheet plastics are coated with a plastic coating to improve its use in humid environments. The disadvantages to this type of sheet plastic are that it has a medium cost and is not very durable. The advantages with this material are its multiple uses, ability to withstand humid and cold environments, and ability to be handled by conveyors, AGV, or other power unit load transportation devices.

Plastic sheet

The plastic sheet plastic is made from recycled high density polyethylene or polypropylene materials. This type of material allows for greater non-tear strength and an increased number of uses in cold and humid environments. The only disadvantage to the plastic sheet plastic is the high cost. Yet, its advantages include longer sheet life, durable lips, ability to be stored in cold or humid environments, and can be handled by a roller conveyor, sheet plastic lift truck, AGV, or powered unit load transportation devices.

Sheet plastic vs. pallet

When considering the use of a sheet plastic vs. a pallet, there are several advantages and disadvantages associated with both.

Sheet plastic advantages

- Using sheet plastics instead of wooden pallets allows for 12-15% more products in material handling containers.

- Sheet plastics do not require maintenance, but can easily be replaced.

- Significant reduction in material handling costs.

- Decreases loading/unloading time by up to 60%

- Weighs 20 times less than wooden pallets, saving shipping weight.

- Can be customized to fit any size load.

- Eliminates the need for pallet exchange.

- Reusable and reliable.

- Most are recyclable.

- Is cost-effective.

- Unlike wooden pallets sheet plastics are not subject to phytosanitary restrictions.

Sheet plastic disadvantages

- Pallets provide a greater clearance between the floor and the unit load. An advantage when loading extra cargo into a container (provides extra cube).

- Sheet plastic usage requires special attachments on transportation devices such as a lift truck (but are fairly cheap).

- When used alone, pallets provide more structural support than sheet plastics.

- Pallets are easily compatible with crane devices.

- Lift truck attachment reduces load capacity. Except when 'Roller Forks' are used.

- Slower handling. Except when 'Roller Forks' are used.

Overall, the advantages of sheet plastics vs. pallets highly overrate the disadvantages associated with the two.

View our sheet plastic products

Not what you're looking for? We also stock and supply;