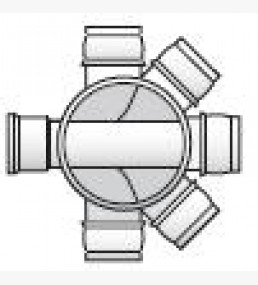

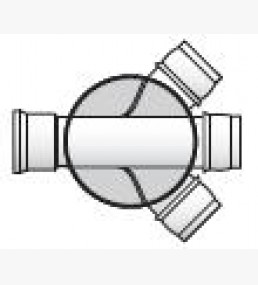

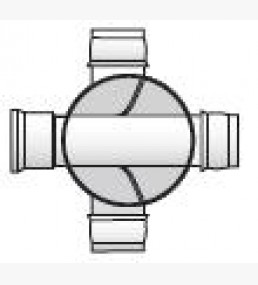

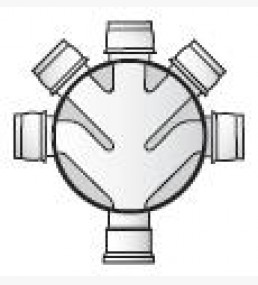

Liv Supplies can supply all product / parts to create a underground drainage system. From super sleeve clay adaptors to plain ended pipes, double socket pipe couplings, junction triple sockets and more. Your will find everything you need for an underground drainage system here.

Drainage Current practices

Modern drainage systems incorporate geotextile filters that retain and prevent fine grains of soil from passing into and clogging the drain. Geotextiles are synthetic textile fabrics specially manufactured for civil and environmental engineering applications. Geotextiles are designed to retain fine soil particles while allowing water to pass through. In a typical drainage system they would be laid along a trench which would then be filled with coarse granular material: gravel, sea shells, stone or rock. The geotextile is then folded over the top of the stone and the trench is then covered by soil. Groundwater seeps through the geotextile and flows within the stone to an outfall. In high groundwater conditions a perforated plastic (PVC or PE) pipe is laid along the base of the drain to increase the volume of water transported in the drain.

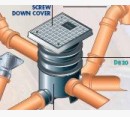

Underground Drainage System

Liv Supplies is able to provide a range of underground drainage system solutions for a range of individual needs and requirements from replacing an old system in the event of a collapse to installing a new underground drainage system during home improvements. There are many different types of material that have been used over the years, any of which could be present in your current underground drainage system, including clay, ductile iron, cast iron and PVCu.

If you are installing a new underground drainage system or altering your existing drainage the you must always inform the Building Control Department at your local council offices. They will require plans showing what work is being undertaken and your finished underground drainage system will need to be inspected to ensure that it complies with the building regulations. You do not need to contact the building control department if you are just replacing damaged section f of your underground drainage system.

There are two common types of underground drainage system:

Foul Water Underground Drainage System:The term foul water applies to any water that comes from kitchens, utility rooms, bathrooms, car washing areas etc. This must always go to your foul water underground drainage system.

Surface Water Underground Drainage System:A surface water underground drainage system is designed to transport rainwater. In older properties however, the existing rainwater pipes are often discharged to your foul water drain in a system known as a combined underwater drainage system. In this case the rainwater pipes are discharged using gully traps to stop foul air escaping from the drains.

Modern systems are designed to keep the surface water and foul water separate using individual drains. This is known as a Separate Underground Drainage System; the rainwater is discharged to a watercourse, soakaway or surface water sewer. Using this method does not create foul air and it is extremely important to ensure you never connect foul water to a surface water underground drainage system.

If you are unsure about the underground drainage system around your house then Liv Supplies would recommend you seek advice from the Building Control Department before starting any work. Underground drainage system pipes must be a golden brown colour to distinguish them from other buried services.

Testing an Underground Drainage SystemAny underground drainage system must be tested prior to being covered over to ensure no leaks are present. If the work you have carried out if subject to Building Regulations your local Building Control Office will need to witness the testing being carried out.

Under normal conditions any underground drainage system pipework and fittings will be supported by the weight of the backfill surrounding the pipe. However, because your underground drainage system will be unsupported during testing the internal pressure may push fittings apart, causing them to leak during the test. You must take precautions against this should you feel there is a risk of it happening.

Old drains must never be tested with water as they may not be able to withstand the internal pressure. New drains and underground drainage systems can be tested using this method.

Green Drain

Enzymatic drain cleaners can be a safer alternative to chemical drain cleaners, and are easier on the environment. They use bacteria or enzymes, which naturally feed on organic waste, such as hair and food waste that often block drains. These tiny organisms, then digest the waste and to recreate beneficial bacteria and enzymes throughout the septic system. In fact, drain cleaners enzyme originally used to clean septic tanks and sewage. Enzymatic drain cleaners are better for the environment because they prevent hazardous chemicals that may leak into soil and water from spreading.

Alternatively, prefabricated plastic drainage systems made of HDPE called SmartDitch, often incorporating geotextile, coco fiber or rag filters can be considered. The use of these materials has become increasingly more common due to their ease of use which eliminates the need for transporting and laying stone drainage aggregate which is invariably more expensive than a synthetic drain and concrete liners.

Over the past 30 years geotextile and PVC filters have become the most commonly used soil filter media. They are cheap to produce and easy to lay, with factory controlled properties that ensure long term filtration performance even in fine silty soil conditions.